Identifying and addressing boiler pressure problems involves a multi-faceted approach. Regular maintenance, including checks for leaks, water levels, and air buildup, prevents high pressure. Understanding normal operating ranges and comparing across models aids in early detection. Upgrading to modern boilers with smart pressure control systems enhances efficiency and longevity. Proactive measures, regular cleaning, and timely servicing are vital to avoid costly repairs and ensure optimal heating system performance.

High boiler pressure can lead to serious issues, from efficiency drops to safety hazards. This comprehensive guide explores six effective solutions for addressing boiler pressure problems. We delve into identifying root causes, implementing critical safety precautions for pressure relief, optimizing burners and fuel systems, scheduling regular maintenance, considering modern upgrades, and monitoring steam pressure effectively. Implement these strategies to ensure your boiler operates safely, efficiently, and reliably.

- Identify Root Causes of High Boiler Pressure

- Implement Safety Precautions for Pressure Relief

- Optimize Burners and Fuel Supply Systems

- Regular Maintenance Checks and Cleaning

- Consider Upgrading to Modern Boiler Models

- Monitor and Regulate Steam Pressure Effectively

Identify Root Causes of High Boiler Pressure

Identifying the root cause of high boiler pressure is a critical first step in resolving any boiler pressure problem. Several factors can contribute to elevated pressure within your boiler system, from issues with the heating element to problems with water levels or even air buildup. Understanding these causes requires careful observation and analysis.

Regularly reviewing a boiler pressure maintenance checklist for homeowners can help pinpoint potential issues early on. Common low boiler pressure causes and cures include checking for leaks, ensuring proper water circulation, and verifying that safety valves are functioning correctly. Implementing these low boiler pressure solutions for homes not only helps maintain optimal pressure levels but also contributes to the longevity of your heating system.

Implement Safety Precautions for Pressure Relief

When addressing high boiler pressure issues, implementing safety precautions for pressure relief is paramount. Boilers operate under strict pressure parameters, and any deviation can lead to dangerous situations. It’s crucial to understand what does low boiler pressure mean – while it might seem counterintuitive, low pressure can indicate problems like air in the system or low water levels, both of which require immediate attention from a qualified technician. To prevent risks associated with high pressure buildup, regular maintenance is key. A comprehensive boiler pressure maintenance checklist for homeowners should include routine inspections, flushing of air bubbles, and checking for leaks, ensuring optimal performance and safety. Additionally, understanding how to stabilize boiler pressure naturally through adjustments like maintaining proper water levels and preventing excessive sediment build-up can contribute to long-term efficiency and prevent costly repairs.

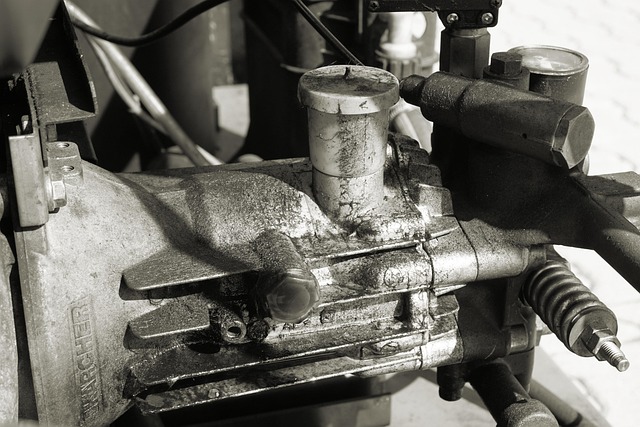

Optimize Burners and Fuel Supply Systems

Optimizing burners and fuel supply systems is a strategic approach to addressing boiler pressure problems, especially in cold climates where lower temperatures can contribute to reduced efficiency. Regularly reviewing and adjusting burner settings ensures the optimal combustion of fuel, which directly impacts steam or hot water production. Modern boilers often come equipped with advanced control systems that allow for precise tuning of air-fuel ratios, minimizing excess oxygen and maximizing energy transfer.

By identifying low boiler pressure symptoms early on—such as inadequate heating or unusual noises—homeowners and facility managers can proactively address the issue. Regular maintenance includes checking for fuel supply disruptions, leaks in pipes or valves, and ensuring proper ventilation. Timely servicing, including cleaning and adjusting components like burners and heat exchangers, prevents significant pressure drops and maintains boiler efficiency over time, preventing costly breakdowns and addressing boiler pressure problems effectively.

Regular Maintenance Checks and Cleaning

Regular maintenance checks and cleaning are essential practices to prevent and address high boiler pressure problems. Over time, buildup of mineral deposits and debris can restrict water flow within the system, leading to increased pressure. A professional plumber Bromsgrove can perform thorough inspections to identify any blockages or issues with the boiler’s components, ensuring optimal performance.

Comparing boiler pressure across different brands and models can provide valuable insights into normal operating ranges. Understanding the boiler pressure settings explanation allows homeowners to monitor and adjust pressures accordingly, preventing excessive buildup. Regular cleaning and maintenance not only resolve immediate pressure issues but also extend the lifespan of the boiler, saving energy costs and reducing the need for costly repairs.

Consider Upgrading to Modern Boiler Models

Many boiler pressure problems can be attributed to outdated equipment and inefficient design. If your system is struggling to maintain optimal pressure, consider investing in a modern boiler model. Today’s boilers are designed with advanced features that enhance energy efficiency, improve temperature regulation, and reduce the likelihood of pressure fluctuations. Upgrading to a newer model could be a game-changer for managing boiler pressure problems.

Regular maintenance plays a crucial role in preventing sudden drops in boiler pressure. While how to increase boiler pressure safely and naturally is a common concern, addressing potential issues like leaks, corrosion, or faulty components can help maintain consistent pressure levels. By understanding what causes sudden drops in boiler pressure, you can implement proactive measures to ensure your system operates smoothly and efficiently throughout its lifespan.

Monitor and Regulate Steam Pressure Effectively

Effectively monitoring and regulating steam pressure is a critical step in addressing and preventing high boiler pressure problems. Plumbers in Bromsgrove recommend implementing smart pressure control systems that can automatically adjust based on real-time data. This involves fitting boilers with pressure gauges and pressure relief valves, which allow for precise tracking of pressure levels and immediate action when necessary. Regular maintenance checks should be conducted to ensure these components are functioning optimally, as well as to identify any potential issues early on.

Comparing boiler pressure across different brands and models can also provide valuable insights into the root cause of high pressure problems. Understanding industry standards and optimal operating pressures for specific types of boilers enables homeowners and professionals alike to better manage expectations and implement tailored solutions. Preventing low boiler pressure build-up is not just about maintaining efficiency; it’s also about ensuring the longevity of your boiler system, minimizing the risk of costly breakdowns, and maintaining optimal indoor comfort levels.

Addressing high boiler pressure problems requires a multifaceted approach. By identifying root causes, implementing safety precautions for pressure relief, optimizing burners and fuel supply systems, conducting regular maintenance checks, considering modern boiler upgrades, and monitoring steam pressure effectively, you can create a comprehensive solution set. Adopting these strategies not only enhances safety but also improves boiler efficiency, ensuring optimal performance and longevity in today’s industrial landscape.