Boiler pressure, influenced by climate, fuel, and water treatment, is crucial for steam boiler performance. Imbalanced setpoints, leaks, or faulty valves cause pressure issues impacting efficiency, safety, and system longevity. Advanced monitoring technologies and regular maintenance address these problems, optimizing energy usage, preventing costly repairs, and ensuring reliable heating systems. Effective boiler pressure control involves regular checks, addressing root causes like malfunctioning components, and adjusting for optimal heat transfer to minimize fuel consumption and enhance sustainability in a competitive market.

In the realm of industrial heating, steam boiler pressure control is a critical aspect often plagued by dynamic challenges. Understanding these dynamics is pivotal to tackling common issues like excessive pressure buildup or instability. This article navigates through intricate topics such as advanced monitoring technologies and cost-effective solutions, offering insights into optimizing energy efficiency through precise pressure regulation. By exploring real-world case studies, readers can gain valuable strategies for successful price comparison, ultimately mitigating boiler pressure problems.

- Understanding Boiler Pressure Dynamics

- Identifying Common Pressure Control Issues

- Advanced Pressure Monitoring Technologies

- Cost-Effective Steam Boiler Solutions

- Optimizing Energy Efficiency through Pressure Regulation

- Case Studies: Successful Price Comparison Strategies

Understanding Boiler Pressure Dynamics

Boiler pressure is a critical aspect of steam boiler operation. Understanding the dynamics of boiler pressure involves grasping how temperature fluctuations, fuel quality, and water treatment impact system performance. In cold climates, for instance, boiler pressure problems can arise due to increased water viscosity and reduced heat transfer rates, leading to lower pressures and potentially decreased heating efficiency.

Maintaining optimal boiler pressure is essential for both hot water supply and energy efficiency. When boiler pressure drops below recommended levels, it can result in inadequate hot water flow or even system failure. Conversely, excessively high pressure can cause premature component wear and increase energy consumption. Regular monitoring and adjustment of boiler pressure control mechanisms are therefore vital to ensure smooth operation, prevent costly repairs, and optimize overall energy efficiency.

Identifying Common Pressure Control Issues

Boiler pressure issues can manifest as a result of various factors, often leading to suboptimal performance and potential safety hazards. Identifying common boiler pressure control problems is an essential step in maintaining efficient and safe operation. One prevalent issue is an imbalanced pressure setpoint, which can be due to incorrect calibration or changes in atmospheric conditions, affecting the accuracy of the pressure regulator.

Another frequent problem is low boiler pressure, often linked to leaks in the system, faulty valve operations, or inadequate heating sources. This not only reduces energy efficiency but also compromises the overall performance of the boiler. In light of these challenges, understanding the underlying causes through proper diagnosis and adopting modern solutions for low boiler pressure can significantly enhance system reliability and longevity. Boiler pressure problem diagnosis plays a pivotal role in addressing these issues, ensuring optimal energy usage and safety measures.

Advanced Pressure Monitoring Technologies

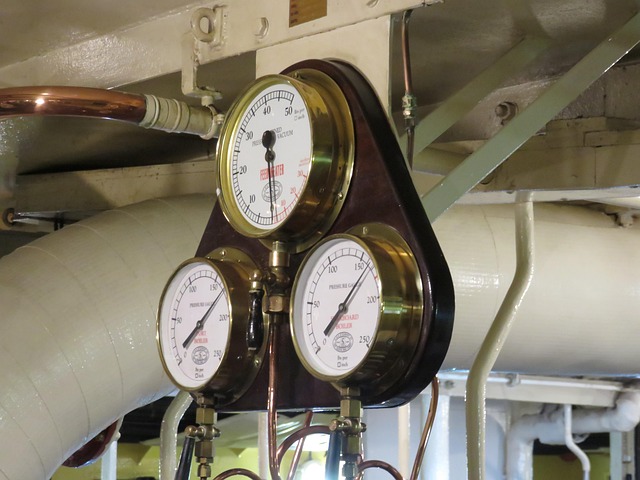

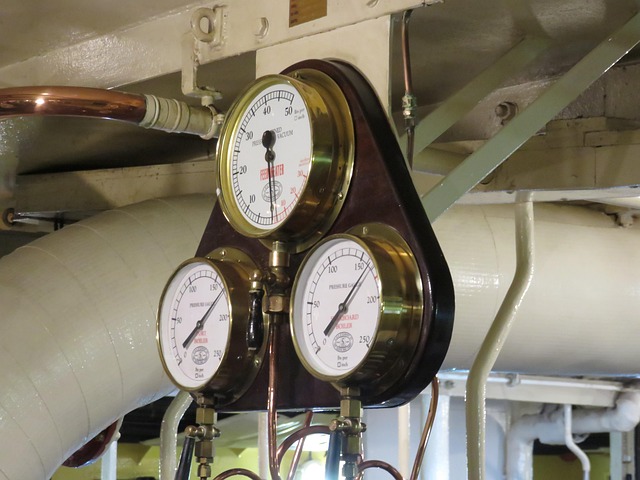

Advanced Pressure Monitoring Technologies play a pivotal role in addressing boiler pressure problems, enabling more precise control and stability. Modern steam boilers are now equipped with sophisticated sensors and data analytics that continuously monitor pressure levels, detecting even subtle fluctuations. This real-time information allows for immediate adjustments to maintain optimal performance and safety.

When comparing boiler pressure across different brands or models, these technologies offer invaluable insights. Users can track not only high and low pressure fluctuations but also identify patterns that may indicate issues with efficiency, maintenance needs, or potential system malfunctions. By leveraging such data, users can make informed decisions when it comes to addressing boiler pressure too low hot water scenarios, ensuring efficient and reliable heating systems.

Cost-Effective Steam Boiler Solutions

In today’s market, a significant focus is on finding cost-effective solutions for steam boiler operations, especially when addressing boiler pressure problems. Many old systems struggle with low boiler pressure build-up, which can significantly impact overall efficiency and performance. By identifying the root causes of these boiler pressure problems—such as what causes low boiler pressure—operators can make informed decisions to prevent potential issues.

One key strategy involves regular maintenance checks to ensure that components like pressure control valves and burners are functioning optimally. Preventing low boiler pressure from the outset not only enhances energy efficiency but also reduces the risk of costly repairs or replacements in the future. With a proactive approach, organizations can maintain reliable steam production while keeping operational costs down.

Optimizing Energy Efficiency through Pressure Regulation

Optimizing energy efficiency in steam boilers involves meticulous control of pressure, a key aspect often overlooked. Boilers with unregulated pressure can lead to significant energy wastage and increased operational costs. Adjusting boiler pressure for optimal heat is an art that ensures fuel combustion is efficient, maximizing heat transfer while minimizing fuel consumption. This precise regulation prevents excessive pressure buildup, which can cause stress on the boiler’s components, leading to premature wear and costly repairs.

Understanding why is my boiler pressure low or what causes low boiler pressure is essential for effective management. Low pressure can result from various factors such as leaks in the system, inadequate fuel supply, or faulty pressure controls. Regular monitoring and adjusting of pressure levels according to the manufacturer’s specifications are crucial practices to maintain energy efficiency. By addressing boiler pressure problems promptly, users can not only enhance operational effectiveness but also contribute to sustainable energy practices.

Case Studies: Successful Price Comparison Strategies

In today’s competitive market, understanding price comparison strategies for steam boiler pressure control is paramount for businesses aiming to optimize their operations while mitigating risks. Case studies reveal that successful firms don’t just focus on initial costs but also consider long-term sustainability and safety. For instance, a manufacturing plant recently faced significant downtime due to low boiler pressure, leading to commercial boiler pressure issues and potential health hazards. However, by implementing a comprehensive price comparison approach, they identified an alternative solution that offered not only lower upfront expenses but also improved energy efficiency, reducing operational costs in the long run.

This strategy involves critically examining various factors beyond the purchase price. It includes evaluating the reputation of suppliers, warranty coverage, after-sales service, and the potential impact on what causes sudden drops in boiler pressure. By factoring in these considerations, businesses can make informed decisions that balance cost savings with the need for reliable, safe, and efficient boiler pressure control systems. This proactive approach ensures not only financial prudence but also operational stability and environmental responsibility.

In conclusion, navigating the complex landscape of steam boiler pressure control is paramount for optimizing energy efficiency and mitigating potential boiler pressure problems. By understanding dynamics, identifying common issues, embracing advanced monitoring technologies, and exploring cost-effective solutions, organizations can significantly enhance their steam boiler performance. The case studies presented offer a testament to successful price comparison strategies, demonstrating that strategic pressure regulation is not only feasible but also economically viable in today’s market.