Understanding boiler pressure readings (psi) and normal ranges (12-15 for residential) is crucial for diagnosing issues like leaks, valves, or low water levels below typical ranges, or overpressure above ranges due to blockages. Conduct visual inspections for damage, corrosion, cracks, and discolouration. Regularly inspect fuel lines, combustion air filters, and maintain steam/water quality sensors for accurate pressure control. Calibration, maintenance, and comparisons across models help identify anomalies caused by sediment buildup or faulty components leading to low boiler pressure.

Diagnosing boiler pressure issues is crucial for maintaining optimal system performance and safety. This guide outlines essential steps to identify problems in your boiler’s pressure system. First, understand normal operating ranges and pressure readings. Next, visually inspect for damage or leaks. Check fuel supply lines and combustion air filters for blockages. Additionally, ensure the accuracy of steam/water quality and level sensors. By following these steps, you can effectively navigate and resolve common boiler pressure problems.

- Understand Boiler Pressure Readings and Normal Operating Ranges

- Inspect Boiler for Visual Signs of Damage or Leaks

- Check Fuel Supply Lines and Combustion Air Filters

- Analyze Steam/Water Quality and Level Sensors Accuracy

Understand Boiler Pressure Readings and Normal Operating Ranges

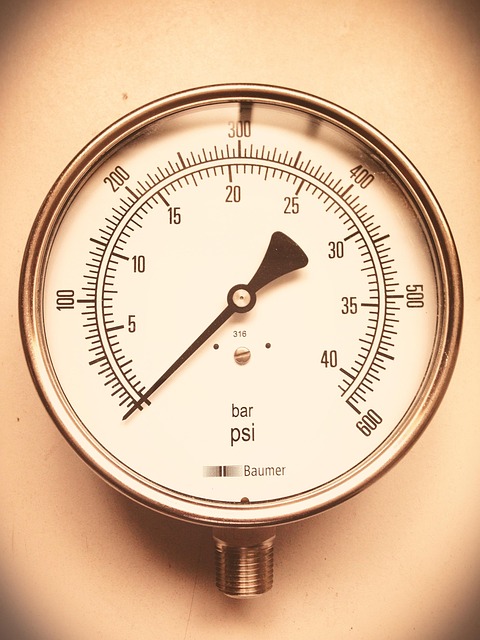

Understanding boiler pressure readings is crucial when diagnosing any pressure-related issues. Boiler pressure is typically measured in pounds per square inch (psi) and indicates how much force steam or water exerts against the walls of the boiler’s vessel. Normal operating ranges vary depending on the type and model, but generally, a healthy boiler will maintain pressure between 12-15 psi for most residential systems.

Knowing what constitutes normal operation is essential when recognizing potential problems. A sudden drop in pressure below the established range may indicate issues like leaks, faulty valves, or low water levels. Conversely, persistent pressure readings well above the typical range could signal issues with overpressure relief valves, incorrect fuel-to-water ratios, or blockages within the system. Understanding boiler pressure control mechanisms and following boiler pressure reset instructions can help maintain optimal performance and prevent potential boiler pressure problems.

Inspect Boiler for Visual Signs of Damage or Leaks

Before diving into complex diagnostic procedures, start with a visual inspection of your boiler. Damage or leaks can be easily spotted and often point to specific boiler pressure issues. Check for any signs of corrosion, cracks, or worn-out seals, which could indicate problems that lead to low boiler pressure. Also, look for unusual markings or discolouration on the exterior, as these may suggest heat-related damage.

This initial step is crucial in troubleshooting boiler pressure problems. If you notice any visual abnormalities, it’s important to address them promptly. Understanding the low boiler pressure causes can guide your actions towards effective solutions, and even offer ways to increase boiler pressure naturally, depending on the issue at hand.

Check Fuel Supply Lines and Combustion Air Filters

Regularly inspecting and maintaining your boiler’s fuel supply lines is an essential step in preventing boiler pressure problems. These lines are responsible for delivering fuel to the boiler, and any blockages or damage can significantly impact pressure levels. Check for signs of corrosion, leaks, or obstructions. Replace any worn-out components and ensure a steady flow of fuel to maintain optimal pressure.

Similarly, combustion air filters should be examined and cleaned or replaced as needed. Clogged filters restrict the intake of fresh air, affecting the burning process and leading to low boiler pressure in homes or commercial settings. Modern solutions for low boiler pressure often involve implementing these simple yet effective maintenance practices to ensure your boiler operates efficiently and prevents further complications.

Analyze Steam/Water Quality and Level Sensors Accuracy

Analyzing the accuracy of steam and water quality sensors is a critical step in diagnosing any boiler pressure issues. Boilers heavily rely on precise measurements to maintain optimal pressure levels, and inaccurate readings can lead to serious problems. Regular calibration and maintenance checks are essential to ensure these sensors function correctly. By comparing boiler pressure across different brands and models, you can identify anomalies and potential sources of disruption. This process involves scrutinizing the quality of the steam or water, including its temperature, pH level, and any impurities that could impact pressure regulation.

Inadequate sensor accuracy can result in low boiler pressure, which has various causes and cures. For instance, sediment buildup or faulty gaskets might reduce water levels, affecting overall pressure. Corrective actions include draining and cleaning the system or replacing defective components. Maintaining optimal boiler pressure levels through thorough inspections and timely maintenance is key to preventing such issues from escalating.

Identifying and diagnosing boiler pressure issues is a multi-step process that requires careful attention to detail. By understanding normal operating ranges, visually inspecting for damage or leaks, verifying fuel supply lines and combustion air filters, and ensuring the accuracy of steam/water quality sensors, you can effectively navigate through potential boiler pressure problems. Remember, prompt action on these steps is key to maintaining optimal system performance and preventing costly breakdowns.